Last updated on

Harness the power of a water hose repair kit because it can resurrect your failing hose, restoring its efficiency and reliability.

Key takeaways:

- Various types of water hose repair kits cater to different needs.

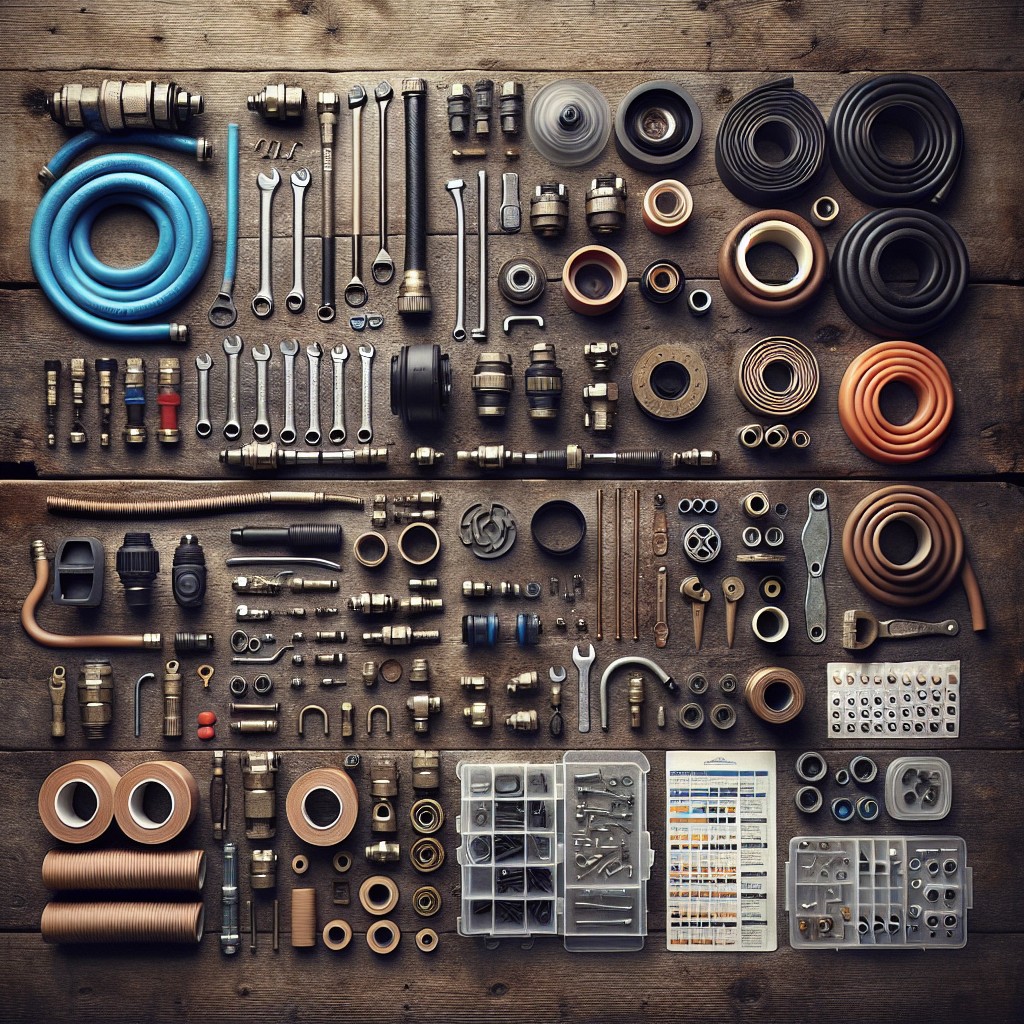

- Components of a hose repair kit include couplings, hose clamps, replacement washers, hose menders, and an instruction manual.

- Steps for repairing a damaged hose include cutting out the damaged section, inspecting hose ends, choosing the correct fitting, inserting the fitting, and securing the connection.

- Plastic and metal/brass repair kits have different durability and longevity.

- Consider specific criteria for high-pressure applications when selecting a repair kit.

Table of Contents

Types of Water Hose Repair Kits

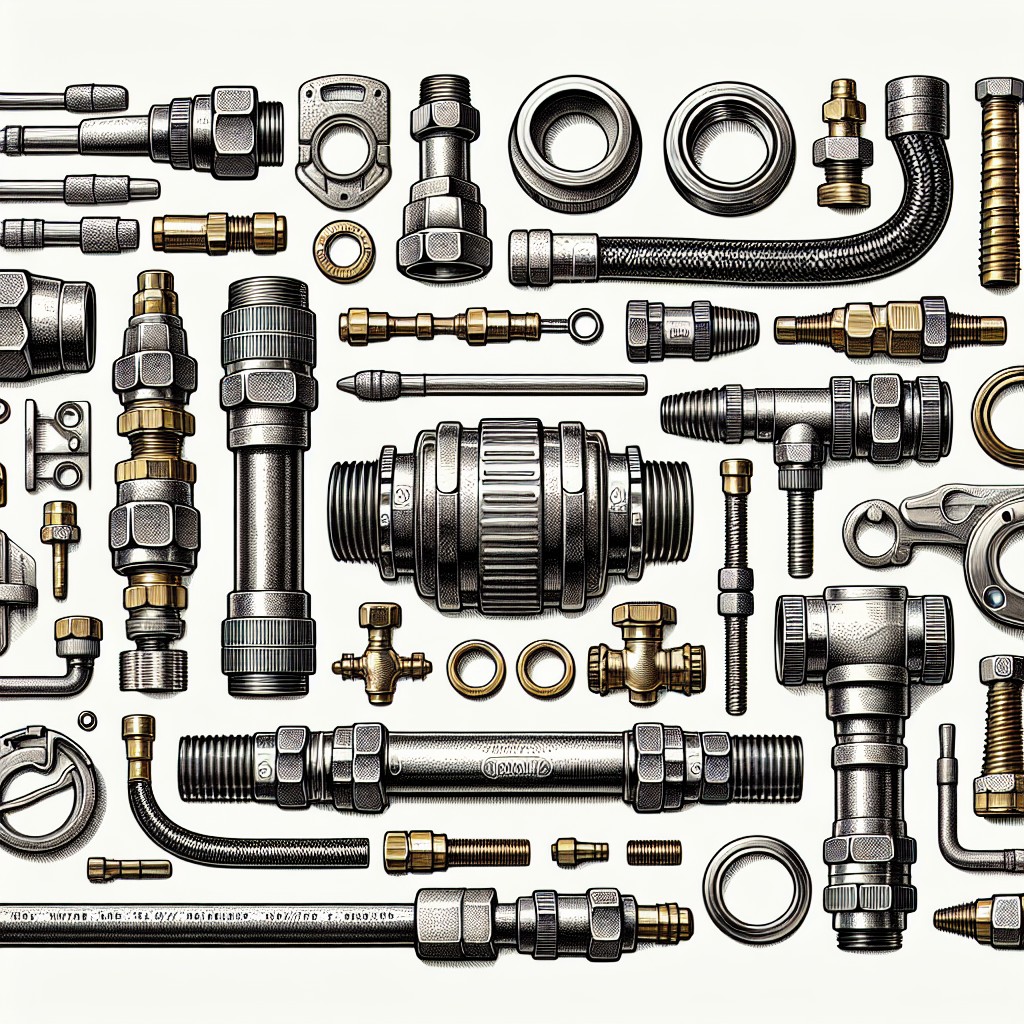

Various kits cater to different needs, from simple residential fixes to more complex industrial repairs. Clamp-style kits are great for quick fixes and provide a durable hold, often used for low to moderate pressure situations. Barb connector kits require a more hands-on installation, involving a fitting being inserted between two hose pieces and secured with clamps. Push-fit connectors offer hassle-free installations but are generally best suited for low-pressure applications. For a long-lasting solution, particularly in high-pressure environments, heavy-duty kits with metal or brass connectors and crimping tools promise a sturdy and reliable repair, mitigating the need for frequent replacements.

Each type varies in price, durability, and ease of installation, making it essential to match the kit to the specific demands of the repaired hose.

Components of a Hose Repair Kit

A typical hose repair kit provides the essential parts to fix a puncture or tear in a garden hose effectively. These components usually include:

- Couplings or Connectors: These are the fittings that join the two hose ends together. Depending on your hose type, you’ll find male or female connectors, or sometimes both in a single kit.

- Hose Clamps: These metal or plastic bands wrap around the outside of the hose to secure the couplings in place, ensuring a tight seal.

- Replacement Washers: Rubber washers are critical for preventing leaks at the connection points. They’re placed inside the couplings and sometimes need replacing over time.

- Hose Mender: If the hose is damaged in the middle, a mender, usually a small tube or a sleeve, is provided for splicing and joining the hose sections.

- Instruction Manual: Clear instructions guide you through the process of repairing the hose, ensuring the damaged area is restored to good working order.

These components are designed for easy application, making it straightforward to extend the life of your garden hose without needing advanced tools or technical know-how.

Steps for Repairing a Damaged Hose

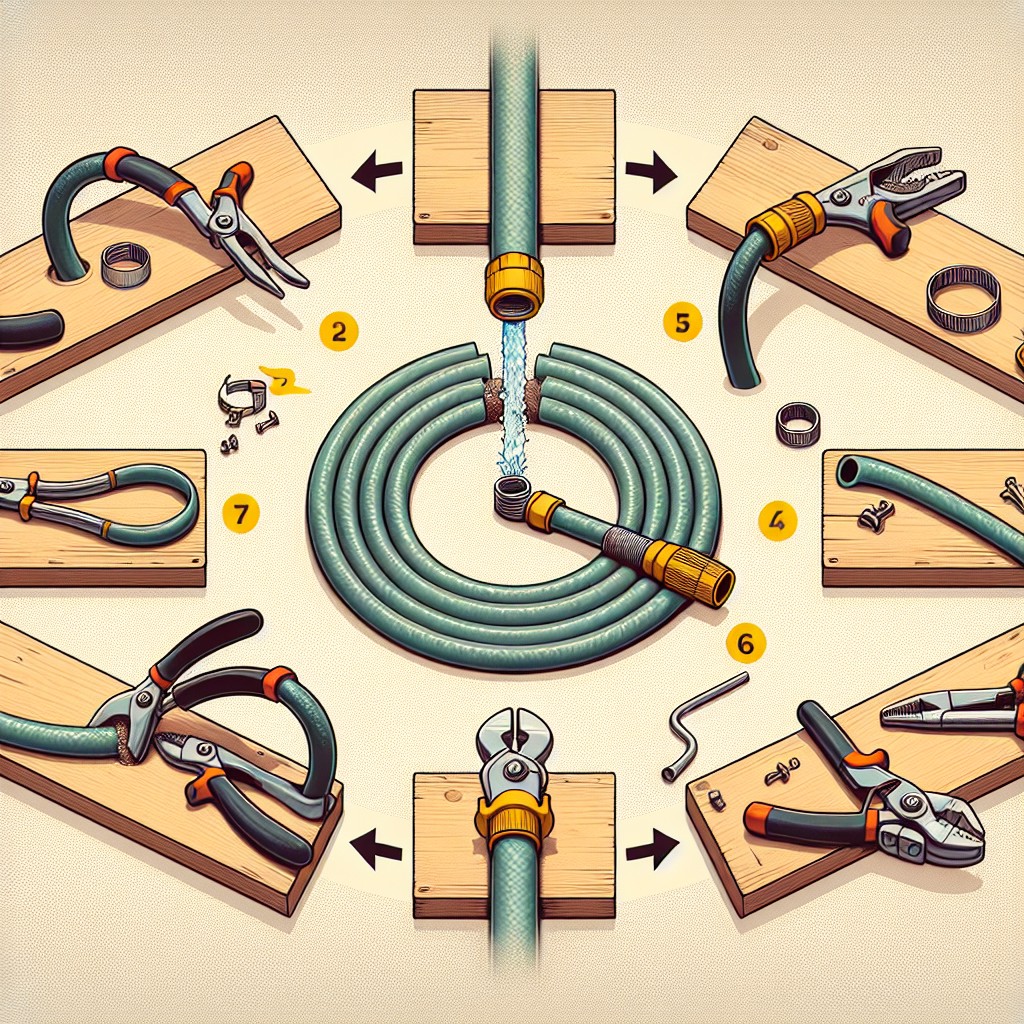

To successfully repair a damaged hose with a repair kit, follow these simple steps:

1. Cut Out the Damaged Section: Use a sharp knife or scissors to cleanly remove the damaged hose segment. Ensure the cut is straight to prevent leaks.

2. Inspect the Hose Ends: Check that the remaining ends are free from cracks and debris.

3. Choose the Correct Fitting: Select the appropriate connector from your repair kit, matching the hose’s diameter and type.

4. Insert the Fitting: For a compression fitting, firmly push the cut hose end onto the connector until it’s snug. If the kit requires a clamp, slip it on before attaching the hose end.

5. Secure the Connection: Tighten the clamp with a screwdriver or use the provided hardware to secure the fitting. Ensure it’s tight enough to prevent leaks but not so tight that it damages the hose.

6. Test the Repair: Before using, turn on the water to check for leaks. Ensure the repaired area is holding up under water pressure.

By following these steps promptly, you can extend the life of your hose and save resources.

Comparison of Plastic Vs. Metal/Brass Hose Repair Kits

When choosing between plastic and metal/brass repair kits, consider durability and longevity.

Brass kits typically offer a sturdier fix and can withstand higher water pressure, temperature variations, and general wear and tear over time, making them ideal for heavy-duty or outdoor operations.

Plastic kits, while more cost-effective, are prone to crack or degrade faster, especially when exposed to harsh weather conditions or UV rays.

However, they might be sufficient for light-duty indoor use where stress on the hose is minimal.

Metal kits also boast superior threading grip, reducing the likelihood of leaks at the repair point.

It’s important to match the kit to the specific needs of your hose to ensure a lasting repair.

Suitability for High-Pressure Applications

When selecting a repair kit for a high-pressure hose, consider the following criteria to ensure the longevity and safety of the repair:

- Material Durability: Kits with metal or brass components are often more resistant to the strain caused by high pressure, as opposed to plastic varieties.

- Clamping Mechanism: Look for clamps that can withstand high-pressure without slipping or breaking. Screw clamps or barbed fittings with compression rings offer a more secure connection.

- Hose Compatibility: Verify that the kit is compatible with the specific diameter and material of your hose to maintain pressure integrity.

- Seal Quality: A high-quality washer or o-ring within the kit is crucial to prevent leaks and maintain the pressure inside the hose.

- Manufacturer Recommendations: Some manufacturers offer kits designed specifically for their high-pressure hoses – using these can ensure an optimal fit and performance.

Product Spotlight: RP-RIMR-B PRO Brass Male Thread Hose Repair Kit

The RP-RIMR-B PRO Brass Male Thread Hose Repair Kit stands out for its durability and ease of use. Crafted from high-quality brass, this kit is designed to withstand the rigors of both residential and commercial gardening tasks, providing a reliable solution for mending hoses with male-threaded ends.

It is compatible with standard garden hoses, usually with a 3/4-inch diameter, making it a versatile choice for general hose repair needs.

Key features include the robust clamp design, ensuring a tight and secure fit that guards against leaks. Installation is straightforward; simply cut away the damaged section of your hose, insert the cut end into the repair kit’s coupling, and tighten the clamp screws using an ordinary screwdriver—no special tools required.

This kit’s solid brass construction offers superior rust resistance, ensuring long-term performance without corrosion typically associated with lesser quality materials. The inclusion of a rubber gasket helps create a watertight seal at the point of connection, further enhancing this kit’s effectiveness.

Additionally, the RP-RIMR-B PRO’s sleek design not only repairs your hose but contributes to a polished, professional appearance for your garden tools ensemble.

Maintenance Tips for Extending Hose Life After Repair

Regularly inspect for wear and tear, especially at the hose connections and along the body to catch issues before they escalate.

Store your hose properly when not in use; keep it coiled without kinks and avoid leaving it exposed to the sun for long periods, as UV rays can degrade the material.

Use a hose reel or hanger to prevent it from lying on the ground, which can contribute to abrasion and damage from foot traffic or garden equipment.

Drain water from the hose after use to prevent pressure build-up that can stress the hose material, particularly in climates where water can freeze and expand inside the hose.

Avoid exceeding the recommended water pressure and water temperature for your hose, as this can lead to premature wear or damage.

Make gentle bends rather than sharp turns with the hose to prevent kinking, which can weaken the hose over time.

Treat couplings with care by avoiding overtightening and using rubber washers to ensure a tight fit without stressing the connection points.

Understanding Hose Thread Damage and Repair Options

Hose thread damage commonly occurs from cross-threading or over-tightening connections. Recognizing the signs is the first step to a successful repair. Look for threads that appear flattened, worn, or have metal shavings indicating they’ve been stripped. It’s also important to check if the leak source is from the connection point, which suggests thread issues.

When it comes to repair options, there are several routes you can take:

- Cutting Off the Damaged End: If there’s enough length on the hose, simply cut off the damaged section and attach a repair kit to the new, undamaged end.

- Thread Taps: For minor damage, a thread tap might recondition the threads without needing to cut away any part of the hose.

- Replacement Couplings: Damaged female or male ends can be replaced with new couplings. Choose a coupling that matches your hose diameter and the thread type (standard garden hose thread, or NPT for some professional hoses).

- Hose Repair Kits: These kits typically include clamps and replacement ends. Make sure to match the size and thread type of your hose to the kit you purchase.

Reminder: always ensure the water supply is turned off before starting any repair and follow the kit’s instructions closely for the best results.

Identifying Common Hose Damage That Requires Repair

Recognizing the signs of hose damage is crucial for timely repairs and continued functionality. Common types of damages include:

- Punctures: Small holes can cause leaks, reducing water pressure and wasting water.

- Cracks: Cold weather or wear-and-tear can lead to cracks, which may expand over time and lead to hose failure.

- Bursting: A hose can burst due to high water pressure or deterioration of the material, resulting in a major leak.

- Coupling Damage: The end fittings, or couplings, can become bent or disconnected from the hose, leading to leaks or the inability to connect to faucets or accessories.

- Abrasions: Frequent dragging over rough surfaces can wear down the hose’s exterior, leading to potential leaks.

Spotting these issues early on allows for prompt repair, which can extend the life of the hose and maintain efficient water use.

Customer Reviews On Hose Repair Kits

Feedback from individuals who have used hose repair kits often sheds light on their effectiveness and ease of use. Positive reviews typically highlight the straightforward installation process, with users appreciating clear instructions and a good fit for various hose types. Durability is another commonly praised aspect, especially when the kit components are made of heavy-duty materials like brass.

On the other hand, there are occasional mentions of kits with poorly machined parts or clamps that fail to provide a tight seal, leading to leaks. Some users suggest that including extra washers or o-rings would be beneficial. Lastly, customer service experiences play a role in overall satisfaction; availability of support and a hassle-free return policy can significantly impact a user’s willingness to recommend the product to others.