Last updated on

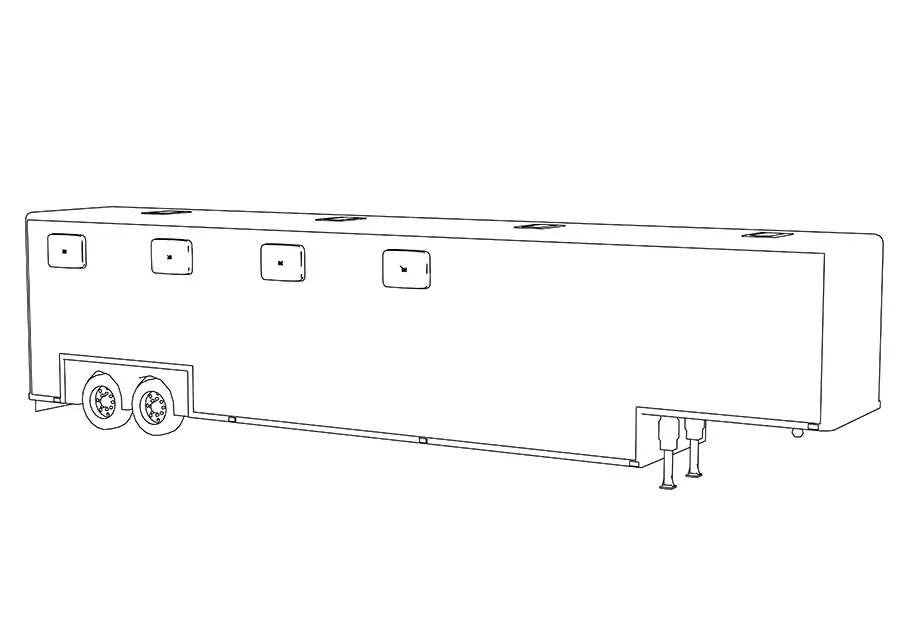

Building a cargo trailer is an achievable project because it allows for ultimate customization capacity, making it a unique possession tailored to individual needs.

Building a cargo trailer requires a combination of technical know-how and practical skills. It involves crafting a sturdy frame, installing walls and flooring, and attaching wheels and a hitch for mobility.

This article will guide you through the process step-by-step, from gathering materials to the final touches. Whether you’re an experienced DIY enthusiast or a beginner, this comprehensive guide will ensure you’re well-equipped to handle the task at hand.

So, let’s jump right into the details of constructing your own cargo trailer.

Key takeaways:

- Determine primary use: heavy or light goods, long or short journeys.

- Choose materials: steel for heavy-duty, aluminum for lighter usage.

- Consider axle types: single for smaller loads, double for heavier loads.

- Review towing vehicle’s capacity: weight must not exceed capacity.

- Gather necessary materials: sturdy steel frame, aluminum or fiberglass exterior, plywood panels, fastening tools, wheels and tires.

Table of Contents

Understanding the Basics of Cargo Trailer Construction

Embarking on cargo trailer construction requires a grasp of some foundational elements. The most pivotal consideration is determining the primary use of your trailer, whether it’s for hauling heavy or light goods, or for long or short journeys. This helps ascertain the correct size and the type of materials to be used.

Steel is a reliable choice for heavy-duty usage while aluminum works well for lighter usage.

Another crucial aspect is understanding axle types. A single axle is apt for smaller loads and more economical. However, for heavier loads or interstate travel, a double axle trailer proves more stable and safe.

Lastly, keep in mind the towing vehicle’s capacity. The combined weight of the trailer and the load it carries should not exceed this. Remember that having a clear understanding of these elements eases the construction process and guarantees a more functional and durable cargo trailer.

Gathering Necessary Materials for Cargo Trailer Construction

To kick off the project, it’s only fitting that we have all the essential elements at our disposal. Aiming for precision and effectiveness, we need a substantial base, preferably, a sturdy steel frame to provide the necessary support.

The exterior of the trailer calls for robust and durable material – aluminum or fiberglass work wonders here. Plywood panels will serve as the interior walls and floor, offering a mix of strength and weight economy.

Does it sound a bit too plain? Fret not, as paint will bring personality and visual appeal to your creation, while waterproofing ensures longevity. Remember, rust and corrosion are the bane of any cargo trailer.

Glue, screws, and other basic fastening tools will join the party, ensuring your masterpiece stays secure while on the road. Don’t forget the electronics for the tail lights and electricity, they’re vital for safety and usability.

Finally, an appropriate set of wheels completes the list. Size and load rating should match the trailer’s intended weight and use. Equally important are the tires – they must be able to effortlessly shoulder the burden they carry for miles on end.

That’s just about everything, without delving into specifics. Take a moment to review this list. Preparing materials before beginning construction will help sidestep any inconvenient surprises down the line.

Steps to Design a Cargo Trailer

After gathering necessary materials, design serves as the fundamental element in constructing a robust cargo trailer. Start with a sketch, outlining the desired size, shape, and space allocation. Ensure the design accommodates the weight load while prioritizing stability and mobility. Use graph paper to draw a scaled model, detailing measurements with accuracy. Consideration should be given to additional features like doors, windows, or compartments.

Next, plan the internal layout signifying the position of shelving, hooks, tie-downs etc, based on cargo type. Sketch potential placements ahead for ease during the assembly.

The axle’s positioning merits attention, with 60% of the weight in front of it. Improper placement can lead to fishtailing or swaying. For the hitch, match it to the towing vehicle’s capacity, ensuring it can support the weight.

Lastly, regulations vary. Therefore, familiarize with local laws regarding trailer construction to make certain your design remains compliant with safety standards.

Building the Cargo Trailer Frame

Laying a solid foundation with the cargo trailer frame is a cornerstone of this project.

Start by measuring and cutting your steel tubes to the correct size based on your design. Accuracy is key in this step as it will influence the fit of other components later on. After cutting, align these pieces on a flat surface to form the shape of your trailer.

Next comes the welding process. Ensure all the joints fuse well together. The use of a welding machine requires both skill and safety precautions – always wear protective gear.

The resulting structure forms the skeleton onto which walls and the roof will be affixed. Strengthen the frame by adding cross members. Also consider installing a tongue, which will connect to the towing vehicle.

Finally, remember to install the axles and wheels to your frame. Aligning them correctly is critical to ensure smooth movement and equal weight distribution when the trailer is loaded.

Remember that a robustly built frame is key to building a reliable cargo trailer.

Installation Process of the Cargo Trailer’s Walls and Roof

After successfully constructing the frame, anchorage of the walls and roof form the next pivotal stage. Accuracy during this phase is integral to the overall stability of your cargo trailer.

1. Start with the Walls: The essence here is vertical alignment, attaching them securely to the trailer frame. Using screws, bolt the bottom part of the walls to the frame. Ensure they align perfectly with the corners of the frame for increased rigidity.

2. Corner Bracing: Reinforce the corners of the walls with metal braces for added structural strength. Screw these into place tightly, ensuring no gaps are present.

3. Roof Installation: Preferably, use a single piece of material to promote waterproofing and strength. Be sure to align and fix it accurately, similar to the walls. If the roof material requires screwing, silicone sealant is advisable to prevent water leakage.

4. Sealing a Roof: Caulk around the edges of the roof, preventing leaks. Use a weather-resistant type for longevity.

5. Add Trim: Lastly, attach metallic trim around the corners of the trailer. It provides an aesthetic finish and adds to the trailer’s structural integrity, preventing any water ingress.

Fitting Essential Components in the Cargo Trailer

Delving right into the process, choose the appropriate location for your doors and windows. The measurements should be precise to ensure a tight and secure fit that minimizes leakage and drafts.

Lights and electrical wiring come next. Hire a professional for this step if you’re uncertain. Any safety breaches on this part could lead to complications.

The cargo area usually includes tie-downs, which can be installed according to the nature and weight of the load you anticipate carrying.

Installing flooring is crucial and depends much on your anticipated use. Wood and aluminum are both common flooring materials, with wood being easier to install and replace, while aluminum provides durability.

The air conditioning system and heat vents are equally essential. Many cargo trailers will have roof-top air units and heat vents near the floor, make sure to install them correctly to maintain comfort.

As you progress, always remember to refer back to your initial design and make adjustments as needed, while ensuring all components installed fit well and operate optimally.

Tips for Maintaining Your Cargo Trailer

Regularly inspecting your cargo trailer ensures its longevity and safety. Start with checking the tire pressure as under-inflated tires compromise stability and fuel efficiency. Also, prior to any trip, verify that all lights are functioning correctly including brakes, turn signals, and internal lights.

Proper storage is key to prevent damages from weathering. Always park your trailer on level ground and use a high-quality trailer cover to protect it from harsh elements.

Lubricate moving parts such as doors, windows, and ramp hinges regularly. This not only prevents rusting but also ensures smooth operation.

Remember, moisture is a trailer’s worst enemy. After a rainy day or a wash, leave doors and windows open for sometime to let it dry completely to avoid any mold or mildew buildup.

Following these simple yet effective tips can keep your cargo trailer performing at its best for years to come.

FAQ

Is it cheaper to build your own cargo trailer?

Yes, it is often cheaper to build your own cargo trailer as utility trailer kits generally cost less than factory-built trailers due to the elimination of certain costs.

Can I make my own enclosed trailer?

Yes, it is possible to create your own enclosed trailer using a ready-made utility trailer and materials for the floor, wall, and roof, which typically costs about half the price of a pre-made enclosed trailer.

Can you build a trailer from scratch?

Yes, you can build a trailer from scratch by gathering the right tools and materials, or alternatively, you can also choose to assemble a utility trailer kit.

Is it hard to build your own trailer?

Building your own trailer is not challenging for individuals possessing a satisfactory level of mechanical aptitude, having access to a welding machine and basic tools, combined with a sense of adventure.

What essential tools are needed to construct a cargo trailer at home?

To construct a cargo trailer at home, essential tools required include a welder, saw, drill, metal shear, angle grinder, trailer hitch, trailer lights, chains, wiring kit, metal tubing, metal sheeting, plywood, bolts, and screws.

What key components must be considered during the design phase of a DIY cargo trailer project?

When designing a DIY cargo trailer project, you must consider key components such as the purpose of the trailer, size, materials for construction, trailer weight capacity, hitch compatibility, aerodynamics, wheel configuration, and road safety regulations.

Can an old, unused trailer be repurposed into a functional cargo trailer?

Yes, an old, unused trailer can be repurposed into a functional cargo trailer with necessary modifications and repairs.