Last updated on

Delve into the fascinating world of pipe repair clamps because their ingenious design and functionality can save you time, money, and unnecessary stress.

Key takeaways:

- Sealing Mechanism: Utilizes a seal to block leaks in pipes.

- Material Construction: Crafted from durable metals like stainless steel.

- Versatility: Can repair various pipe materials (PVC, copper, steel).

- Adjustable Sizes: Accommodates pipes of different diameters.

- Pressure Ratings: Select a clamp that can withstand pipe pressure.

Table of Contents

Understanding Pipe Repair Clamps

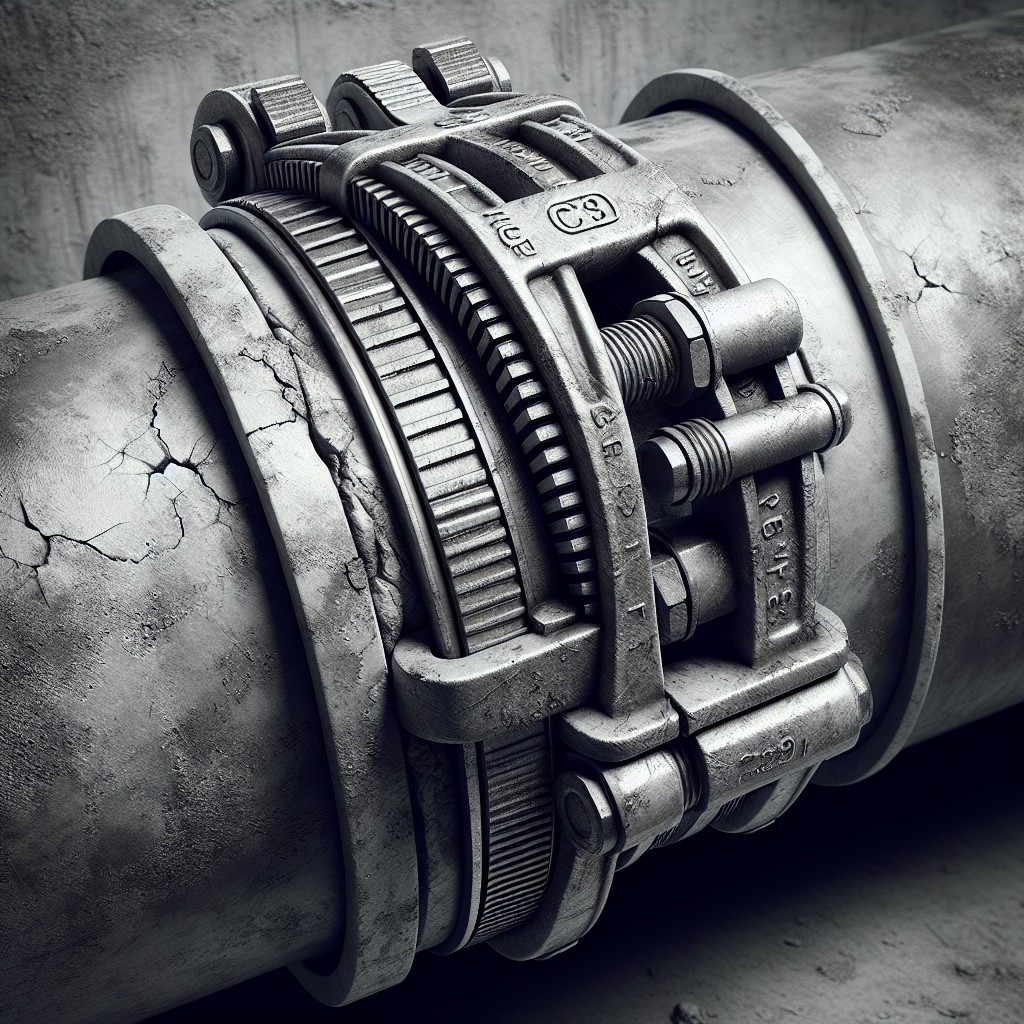

Pipe repair clamps are essential tools for fixing leaks and breaks in piping systems quickly and efficiently. These devices wrap around the damaged area, creating a seal that prevents water or other fluids from escaping. The clamping action is not just a temporary patch but can often serve as a semi-permanent repair solution.

Key points about pipe repair clamps include:

- Sealing Mechanism: They utilize a seal, typically made of rubber or similar materials, which compresses against the pipe to block the leak.

- Material Construction: They are commonly crafted from durable metals such as stainless steel to withstand pressure and environmental factors.

- Versatility: Clamps are designed to mend various pipe materials, including PVC, copper, and steel, making them versatile for multiple scenarios.

- Adjustable Sizes: Many clamps are adjustable or come in different sizes to accommodate pipes of varying diameters.

- Pressure Ratings: It’s important to select a clamp that can withstand the pressure levels within the piping system to ensure a secure repair.

These points highlight the practicality and adaptability of pipe repair clamps in managing unexpected piping issues.

Types of Pipe Repair Clamps

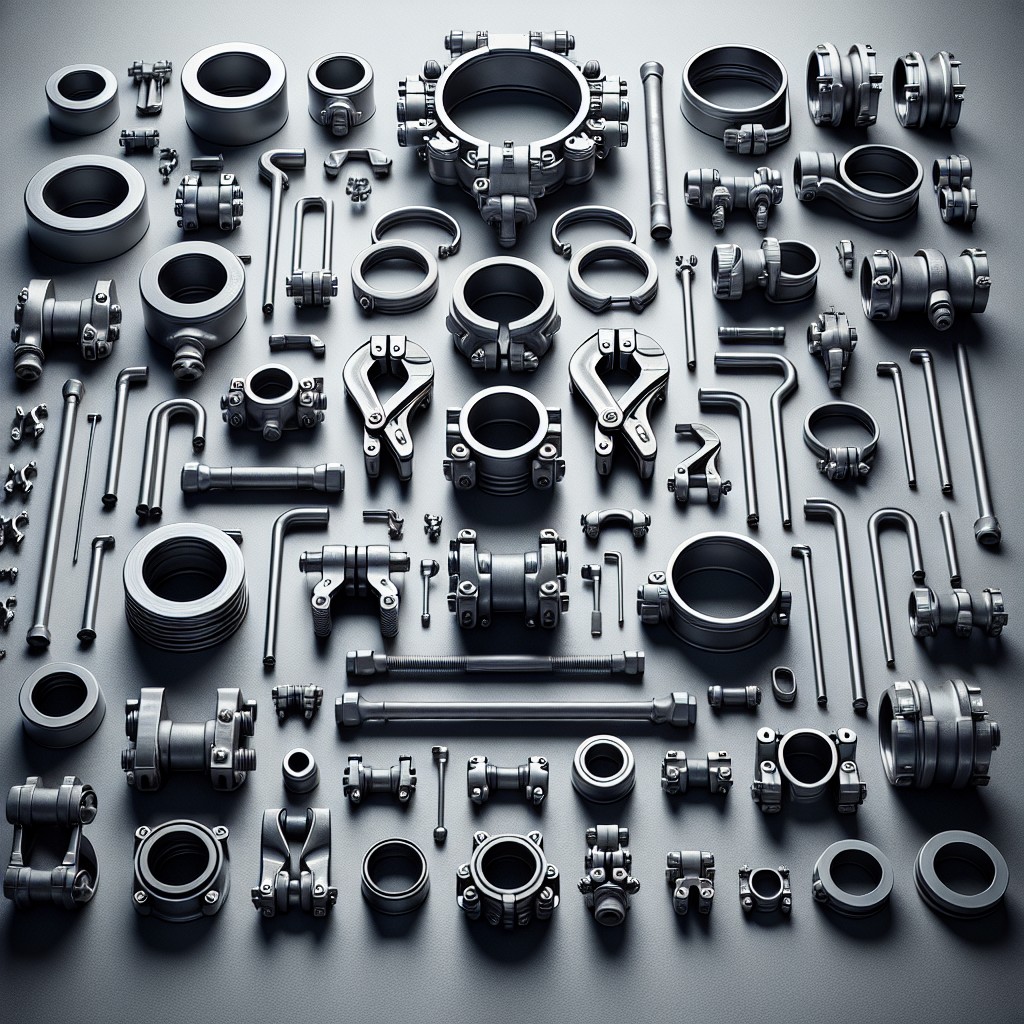

Pipe repair clamps come in various designs, each tailored for specific situations and pipe sizes. The most common types include the full-circle band clamp, which wraps around the entire circumference of the pipe for a secure fit. This type is favored for its ease of use and versatility.

For more localized damage, there are patch clamps that can be applied directly to the site of the leak. These are smaller in size and are often used for temporary fixes until a more permanent solution is implemented.

Hinged clamps, another popular option, are designed for rapid repair as they can be quickly opened and wrapped around the pipe. The hinged mechanism is particularly useful in tight spaces where a full-circle clamp might be difficult to apply.

Reducing clamps also play a critical role when dealing with pipes of differing diameters. These are implemented to transition between sections smoothly without causing disruptions in flow.

Lastly, there are emergency repair clamps that are designed for quick deployment in urgent situations. Often equipped with features such as rubber gaskets and easy-to-tighten bolts, they can halt leaks effectively until professional repairs can be made.

Each clamp type serves a particular purpose, with variation present in materials used, such as stainless steel or rubber, to provide the necessary pressure and seal against leaks. When selecting a clamp, it’s crucial to understand the nature of the damage and the pipe’s specifications to ensure a proper fit and a reliable repair.

Specialty Repair Clamps

Specialty repair clamps offer solutions for unique piping issues that standard clamps can’t address. These specialized tools are designed to fix pipes with unusual leaks or damage. For instance, some clamps are crafted for pipes with a small diameter or those with an odd shape, ensuring a secure fit despite the unconventional structure. Others come with features like a full circumferential gasket, which is ideal for sealing irregular surfaces, or they may have a longer length to cover large defects effectively.

Certain clamps can resist high temperatures or chemical corrosion, making them suitable for industrial applications where pipes are exposed to harsh conditions. When off-the-shelf options do not suffice, customized clamps can be manufactured to meet specific repair requirements. Such bespoke options help maintain system integrity without replacing entire sections of piping, ultimately saving both time and resources.

Installation Steps for Pipe Repair Clamps

First, shut off the water supply to prevent further leakage and ensure a safe environment for repair. Clean the damaged area of the pipe; removing any debris facilitates better adhesion and seal. Measure the diameter of the pipe accurately to select a clamp that fits snugly.

Next, position the repair clamp over the leak, ensuring that the rubber gasket is directly over the damaged section. This gasket is the primary sealing element, so alignment is crucial. Open the clamp and wrap it around the pipe, aligning it carefully before tightening.

Once in place, hand-tighten the bolts to secure the clamp. It’s important to apply even pressure by alternating tightening on opposite bolts. This step prevents the gasket from uneven pressure distribution, which can compromise the repair.

Avoid overtightening, which might damage the gasket or the pipe itself. Inspect the clamp to ensure that it sits squarely on the pipe and is fully covering the area of the leak. After the clamp is installed, slowly turn the water back on and check for leaks. If no water escapes, the repair is successful. If the leak persists, you may need to reposition the clamp or check for other damaged areas.

Factors to Consider When Choosing a Clamp

To ensure a suitable match for your pipe repair needs, several essential elements must be evaluated:

Selecting a clamp with these criteria in mind will lead to a more effective and enduring repair.

Common Applications for Pipe Clamps and Couplings

Pipe repair clamps and couplings play a crucial role in various industries, preventing fluid leakage and ensuring seamless pipe operation. In the water and wastewater sectors, they swiftly fix breaks and holes to maintain the integrity of the distribution system. Gas and oil pipelines, known for their high-pressure requirements, frequently employ these components to provide a temporary or permanent fix, reducing downtime and mitigating the risk of environmental hazards.

Home plumbing systems also benefit from these solutions, particularly when addressing unexpected pipe damage. The ease of application allows homeowners or plumbers to quickly remedy issues without the need for extensive pipe replacement, saving both time and resources.

Irrigation systems, often spread over large agricultural areas, can be prone to damage from machinery or environmental factors. Repair clamps enable a prompt response to damage, ensuring continuous water supply for crops.

In industrial settings, maintaining continuous production is paramount; repair clamps facilitate this by allowing for repairs without halting processes or dismantling machinery.

By accommodating various pipe diameters and materials, these versatile tools are essential for maintaining fluid systems across a spectrum of applications, from household plumbing to vast municipal and industrial networks.

Maintenance and Monitoring Post-Clamp Installation

Regular inspection ensures the longevity and integrity of pipe repair clamps. Visual checks should be carried out periodically to look for signs of corrosion or loosening. If the clamp is installed on pipes that carry water, checking for leaks should also be part of the routine. It’s advisable to clean the clamp during inspections to prevent any build-up of rust or sediment, especially for clamps in harsh or outdoor environments.

Monitoring clamps that have been installed as a temporary fix is critical. They should not be considered a long-term solution. Over time, the repaired section of the pipe may require replacement or more comprehensive repair work.

Lastly, keeping records of the installation date and observations from each inspection can help in predicting wear patterns and planning future maintenance work. With consistent care, pipe repair clamps can provide reliable service and prevent minor issues from becoming major breakdowns.

Addressing Emergency Pipe Repairs With Clamps

In emergency situations where a pipe bursts or develops a severe leak, time is of the essence to prevent extensive water damage. Pipe repair clamps are invaluable tools for such scenarios, providing a quick and reliable temporary fix. Here’s how they come to the rescue:

- Immediate Response: Clamps can be rapidly deployed, halting the leak much faster than it would take to replace the pipe section.

- Versatility: They are designed to accommodate pipes made of various materials and can handle different diameters, ensuring a broad range of situations is covered.

- Ease of Use: Most repair clamps do not require specialized training to install, enabling both professionals and homeowners to secure the affected pipe promptly.

- Reduced Downtime: Clamps help restore partial or full system operation, which is critical in industrial settings where downtime translates to significant financial loss.

- Temporary Solution: Remember that clamps are not permanent fixes. They provide an immediate solution to prevent damage or disruption until a permanent repair can be conducted.

By effortlessly sealing the leak with a repair clamp, you can buy enough time to seek professional assistance while mitigating the risk of further damage.

Brands and Manufacturers of Pipe Repair Clamps

When exploring the options for pipe repair clamps, the market offers a diverse range of brands, each with its own set of features and reputations for quality. Among them:

- ROMAC Industries, Inc. Known for its robust stainless steel clamps that cater to a variety of pipe diameters and types. Their products are typically favored for long-lasting repairs.

- Smith-Blair, Inc. Offers a comprehensive selection of clamps, including full-circle and band types. Their solutions are designed for ease of use and quick installation.

- JCM Industries Specializes in high-quality repair fittings and clamps for all sizes of pipes, focusing on products that ensure a secure and leak-free seal.

- Mueller Co. A well-regarded brand providing a range of water infrastructure and flow control products, their clamps are known for durability and reliability.

Each manufacturer presents unique benefits, such as extended warranties, corrosion-resistant materials, or clamps designed for specific environments. When selecting a brand, consider the application requirements, product reviews, and the technical support provided.

Navigating Clamp Options By Size and Material

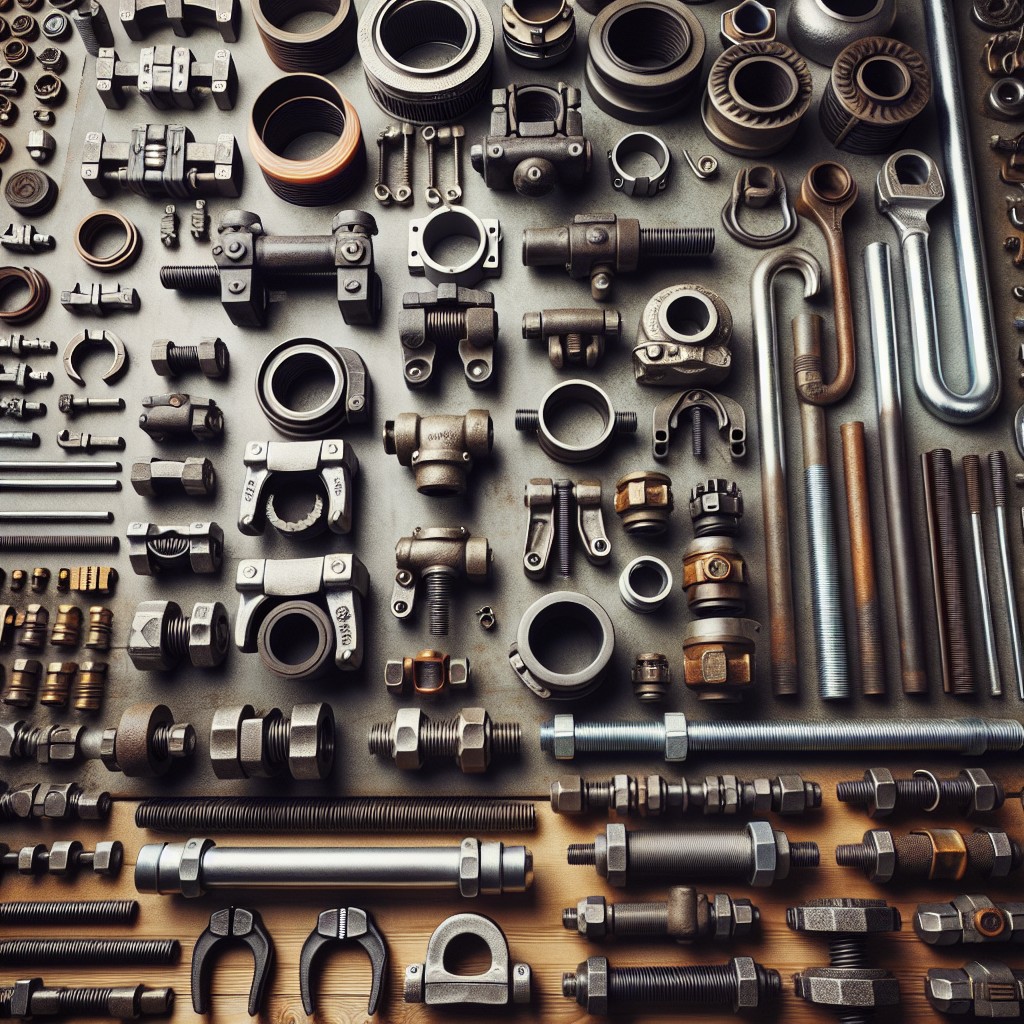

Selecting the right pipe repair clamp involves matching the clamp to the pipe’s diameter and material. Here are a few key points to guide you through the process:

- Measure Precisely: Use a tape measure to determine the pipe’s outer diameter. This will ensure the clamp fits snugly for effective sealing.

- Material Match: Pipes can be made from PVC, copper, steel, or other materials. The clamp material should be compatible to avoid corrosion, often referred to as galvanic corrosion. For example, stainless steel clamps are a versatile choice, resistant to rust, and compatible with many pipe types.

- Gasket Material: The sealing material is just as crucial as the clamp’s metal. Rubber gaskets accommodate a range of temperatures and are commonly used, but there are specialty gaskets for specific conditions.

- Pressure Ratings: Ensure the clamp can withstand the pressure within the pipe, which varies by clamp design and size.

- Environmental Factors: For outdoor pipes, consider UV-resistant clamps to prevent deterioration from sunlight exposure.

By focusing on these aspects, you’ll be well-equipped to select a clamp that ensures a durable and secure repair.